Wonach suchen Sie?

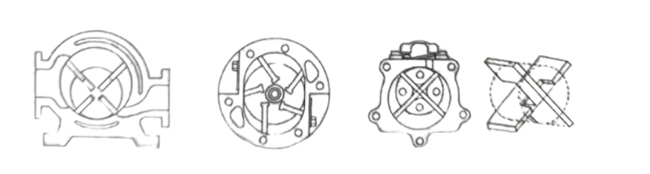

Die Rotorstruktur des Flügelzellenkompressors ist das Herzstück der Anlage. Sein Design und seine Funktion haben direkten Einfluss auf die Leistung des gesamten Kompressors. Das Folgende ist eine Einführung in die Rotorstruktur des Flügelzellenkompressors:

1.Rotorkonfiguration: Der Rotor des Flügelzellenkompressors ist exzentrisch im Zylinder eingebaut. Durch diese exzentrische Konfiguration können die darauf installierten Flügel unter Einwirkung der Zentrifugalkraft bei der Drehung des Rotors eng an der Innenwand des Zylinders anliegen und so eine geschlossene Kompressionskammer bilden.

2. Flügeldesign: Der Rotor verfügt über eine Reihe von Längsnuten, in denen die Flügel frei gleiten. Das Design und die Materialauswahl der Flügel hängen davon ab, wie der Kompressor geschmiert wird. Ölgeschmierte Flügel können aus Kunstharzverbundwerkstoffen oder Metallmaterialien wie Phenolharzlaminaten, Aluminium, Stahl usw. bestehen.

3.Anzahl der Folien:Die Anzahl der Gleitstücke beträgt in der Regel mehr als 4, um Leckagen und mechanische Reibungsverluste zu reduzieren. Bei der Auswahl der Anzahl der Schlitten muss das Verhältnis zwischen Leckagereduzierung und mechanischem Reibungsverlust ausgeglichen werden.

4.Die Übereinstimmung zwischen Flügel und Zylinder: Die Höhe des Flügels beträgt normalerweise das 3- bis 4-fache der Exzentrizität, um sicherzustellen, dass der Flügel ausreichend im Rotorschlitz geführt wird, um ein Verklemmen oder Anomalien zu vermeiden tragen.

5.Zylinderinnenkreis und Enddeckelwand: Der Zylinderinnenkreis und die Enddeckelwand, die zum Schlitten passen, sollten eine geringere Rauheit und höhere Härte aufweisen und werden häufig nitriert oder verchromt, um den Verschleiß zu verbessern Beständigkeit und Rostbeständigkeit.

6.Die Umfangsgeschwindigkeit der Oberseite der Schaufel: Die Umfangsgeschwindigkeit der Oberseite der Schaufel beträgt im Allgemeinen 15 bis 20 Meter pro Sekunde. Bei kleinen Kompressoren oder Kältekompressoren kann diese Drehzahl niedriger sein.

7.Ölfreies Schmierflügelmaterial: Bei ölfreier Schmierung besteht das Schaufelmaterial üblicherweise aus Graphit oder synthetischen Materialien mit selbstschmierenden Eigenschaften, um die mechanischen Eigenschaften und die Verschleißfestigkeit zu verbessern.

Durch diese Konstruktionsmerkmale kann die Rotorstruktur des Flügelzellenkompressors die Gasansaug-, Kompressions- und Auslassprozesse effektiv abschließen und gleichzeitig die Zuverlässigkeit und Effizienz der Ausrüstung gewährleisten.